horizontal ribbon mixer machine manual concrete mixer powder blender Helix type 臥式螺桿混合機

2 min read

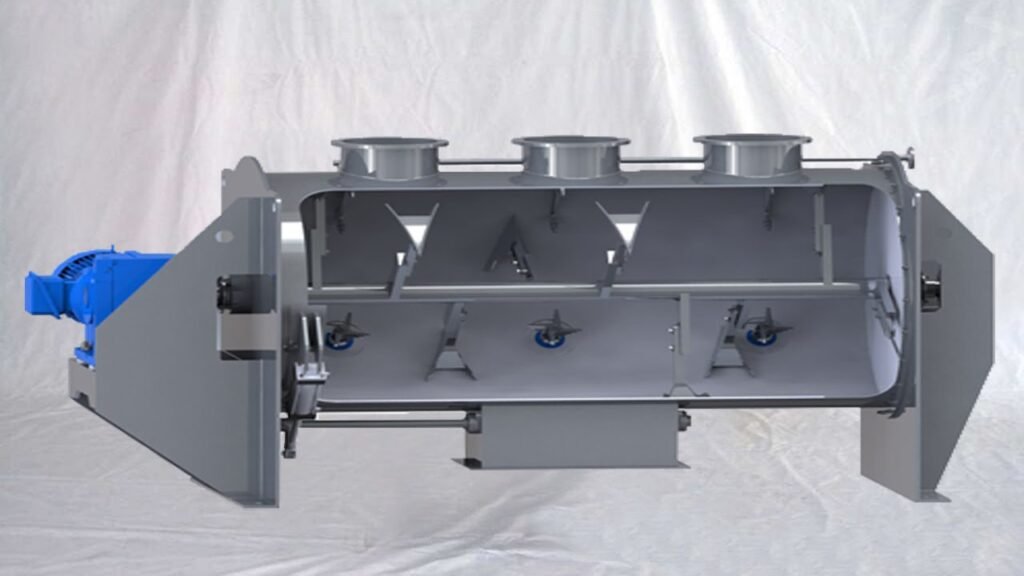

YX Series mixer is mainly comprised of mixing barrel, spiral ribbon and drive parts. The spiral ribbon is made of two layers. That is, the inner ribbon makes the material move outwards, while the external ribbon makes the material move inwards which forms a good circulation of material. Ribbon moves so circumferentially that the mixer could achieve fine mixing efficiency in a very short time.

Application:

YX series Horizontal Ribbon Mixer is a pioneer product researched and a new high-efficiency mixer. It is mainly used in the solid-solid(powder material) and solid-liquid(powder and fluidity material)mixing in the field of chemical industry, pharmacy, foodstuff industry, etc.

basic parameter of YX-200 horizontal ribbon mixer machine manual concrete mixer powder blender Helix type 臥式螺桿混合機:

Model No. Barrel Volume(L) Loading Volume(L) Mixing time(min) Stir Motor(kw) Weight(kg) Size

YX-200 200 100-180 8-20 3-5.5 510 1450*650*1150mm

It consists of container, main shaft, and the drive transmission part. The container is U shape. The machine can be made of Carbon Steel (C model) and Stainless Steel (P model). It can be also equipped with the jacket for the container. It can heat, cool or vacuum in the jacket. The inside pressure of the jacket is less than 0.1 Mpa (The pressure can be customized). Two layers screw ribbons makes the convection of the material to achieve the mixing effect rapidly. There is a discharging valve in the middle of the container bottom. The drive parts adopt separated devices, that is, the motor is connected with reducer by the strap. Thus, It can save the space and has the overload protection.

After-sales service on YX-200 horizontal ribbon mixer machine manual concrete mixer powder blender Helix type 臥式螺桿混合機:

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse,misapplication, storage damage,

negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install

and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After-sale service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible.The cost should be in your account.(as above).

PENGLAI INDUSTRIAL CORPORATION LIMITED

US agent Office

9284 talway cir Boynton beach. fL 33472

Contact: Jack Du

Cel: 0086-15811882441 0086-13077872898

Phone: 0086-20-84206097 0086-755-25423447

Fax: 0086-755—25417648

Email: jackdu999@yahoo.com

Skype: turnanewleaf

Website:

www.penglaimachines.com

www.youtube.com/user/penglaichina

www.youtube.com/user/mrjackdu007

www.youtube.com/user/cosmeticmachines